Typical Properties and Field Applications

FCS technology was commercialized in 2011 successfully and has been applied in various oil and gas fields in the world. It has been proved to be effective in cementing oil or gas wells with the following conditions and properties:

|

Temperature: |

BHST 60-662℉ (15-350℃) |

|

Density: |

8.3 ppg to 23.3 ppg (1.00 – 2.80 g/cm3) |

|

Mix-water: |

Fresh water |

|

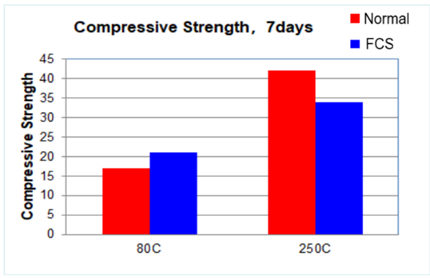

Compressive strength: |

20-30 MPa/200℃ for 7 days |

|

API fluid loss: |

≤50 mL |

|

Treatment Wells: |

Steam injectors, gas storage wells, geothermal wells, unconventional multi-stage fracturing wells |

Typical FCS properties are shown in the following Figures and Pictures.

Elasticity and Compressive Strength of Cement Prepared with FCS and Regular Slurry

Cement Integrity Prepared with Regular and FCS Slurries

Precautions and HSE Considerations

FCS systems include three major additives which are flexible additive

KCM024, DuraCem additive KCM044A and expanding agent KCM025H/KCM025HC. Other

additives such as fluid loss agent, retarder, dispersant are generally used for

controllable rheological, fluid loss, thickening time and stability of FCS

cement slurries. Laboratory tests are required to confirm the compatibility

between FCS additives and other additives to be used in the slurry.

The laboratory procedures, quality assurance

program and guidelines for field mixing and handling of FCS systems are

described in FCS fluid manual.

Refer to the technical sheet and SDS of the

respective product for the health, safety and environmental information of each

product.