Typical Properties and Field Applications

TOC technology was commercialized in 2016 successfully and has been applied in various oil and gas fields in the world. It has been proved to be effective in cementing oil or gas wells with the following conditions and properties:

|

Temperature: |

BHST 104-212℉ (40-100℃) |

|

Density: |

11.20 ppg to 14.50 ppg (1.35 – 1.75 g/cm3) |

|

Mix-water: |

Fresh water |

|

Gel strength: |

YP: 30-100 lbs/100ft2 |

|

Temperature: |

BHST 104-212℉ (40-100℃) |

Further information about field jobs is described in documented “Case History of TOC Technology”.

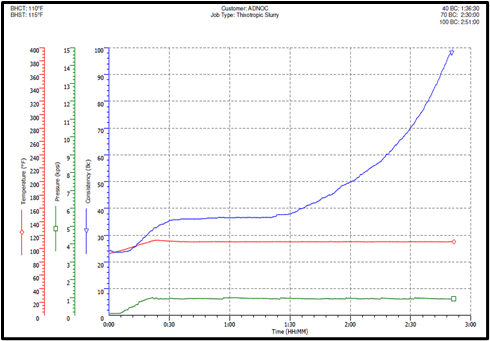

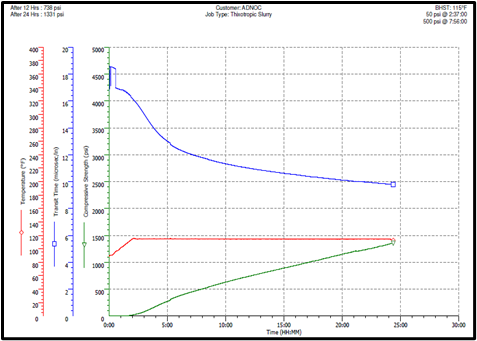

Typical thixotropic properties of TOC slurries are shown in the following Table and Figures.

|

R1-B1-S1 |

RPM |

3 |

6 |

30 |

60 |

100 |

200 |

300 |

PV (cP) |

YP (lbf/100ft2) |

|

80°F |

Ramp Up |

14 |

20 |

42 |

48 |

54 |

62 |

68 |

43 |

32 |

|

Ramp Down |

20 |

26 |

50 |

54 |

56 |

63 |

68 |

|||

|

110°F |

Ramp Up |

45 |

49 |

135 |

179 |

195 |

222 |

236 |

182 |

86 |

|

Ramp Down |

30 |

42 |

120 |

160 |

185 |

213 |

236 |

|||

|

10 sec gel strength (110F) |

33 |

10 min gel strength (110F) |

100 |

|||||||

|

1 min gel strength (110°F) (100 rpm shearing) |

54 |

|

||||||||

Precautions and HSE Considerations

TOC

additive (KCM038) plays the most important role in cementing jobs with TOC

slurry. In addition, fluid loss agent (KCM039), retarder (KCM040) and expanding

agent (KCM025LT, KCM025 and KCM025HC) are engineeringly developed for TOC

system because KCM038 is not compatible with regular fluid loss control agents,

dispersant and retarders.

The

laboratory procedures, quality assurance program and guidelines for field

mixing and handling of TOC systems are described in TOC fluid manual.

Refer

to the technical sheet and SDS of the respective product for the health, safety

and environmental information of each product.