Typical Properties and Field Applications

ELViS spacer technology was commercialized in 2009 successfully and has been applied in various oil and gas fields in the world. It has been proved to be effective in cementing oil or gas wells with the following conditions and properties:

|

Temperature: |

BHST 95-320°F (35-160°C) |

|

Density: |

10.0 ppg to 20.5 ppg (1.20 – 2.45 g/cm3) |

|

Mix-water: |

Fresh water, seawater, and brines |

|

Rheology: |

Adjustable up to 160°C |

|

API mud fluid loss: |

≤50 mL |

Further information about field jobs is described in documented “Case History of ELViS Technology”.

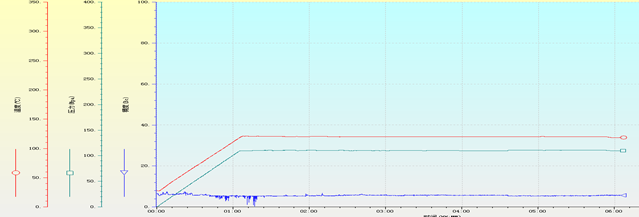

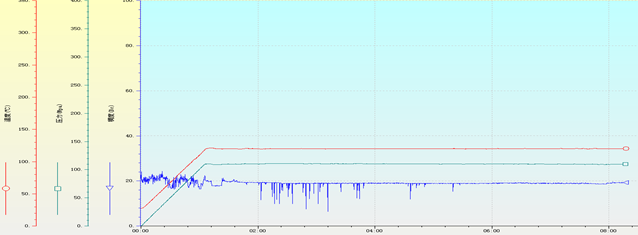

Typical compatibility and thickening time of ELViS spacers are shown in the following Table and Figures.

|

Mud, 1.95g/cm3 |

Rheology at room temperature |

270/169/128/82/15/9 |

| Rheology at 93℃ |

85/55/42/30/7/4 |

|

|

Spacer, 2.05g/cm3 |

Rheology at room temperature |

150/98/78/52/16/15 |

| Rheology at 93℃ |

102/72/59/42/12/11 |

|

|

Lead slurry, 2.10g/cm3 |

Rheology at room temperature |

x/194/138/75/5/4 |

| Rheology at 93℃ |

226/125/89/48/4/3 |

Precautions and HSE Considerations

High

temperature (KCM004) and medium temperature ELViS additive play the most

important role in cementing job design using effective laminar technique. In

addition, defoamer (KCM043) and antifoam agent (KCM003) are also used in ELViS

systems. ELViS density can be easily adjusted with various weighing agents such

as hematite and barite, which are compatible with ELViS additives.

The

laboratory procedures, quality assurance program and guidelines for field

mixing and handling of ELViS systems are described in ELViS fluid manual.

Refer

to the technical sheet and SDS of the respective product for the health, safety

and environmental information of each product.