基本性能和使用条件

SGA technology was commercialized in 2016

successfully and has been applied in various oil and gas fields in the world.

It has been proved to be effective in treatment of carbonate reservoirs with

the following conditions:

Temperature: BHST 60-300F (15-149C)

Formation: Carbonates with

variation in petro-physical properties

Treatment fluids: HCl, self-diverting acids

Mix-water: Fresh water

Further information about field applications is

described in documented “Case History of SGA Technology”.

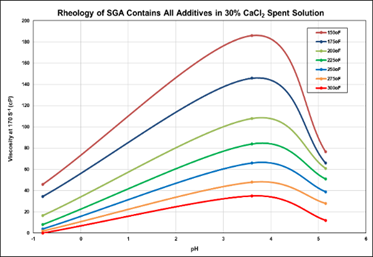

Typical rheological and physical properties of

SGA fluids are shown in the following Figure and Pictures.

注意事项

Acid gelling agent (KMA027G), SGA crosslinker

(KMA024) and SGA iron control agent (KMA022B) in SGA systems play the most

important roles in treatment effectiveness. In addition, corrosion inhibitor

(KMA034C) and inhibitor aid (KMA030 and KMA031) are generally used in SGA

systems to protect the tubing from corrosion. H2S scavenger (KMA009)

and H2S scavenger Aid (KMA009B) are compatible with other system

additives.

The laboratory procedures, quality assurance

program and guidelines for field mixing and handling of SGA systems are

described in SGA fluid manual.

Refer to the technical sheet and SDS of the

respective product for the health, safety and environmental information of each

product.